Home page>>Products>> Polyformaldehyde Plant

Polyformaldehyde is thermoplastic crystallized polymer The nick name is ¡°Super Steel¡± or ¡°Matching Steel¡±, also called polyoxymethylene POM. Usually, the polymer formed from formaldehyde polymerization does not have high polymerization degree and easy to be de-polymerized when heated. Polyformaldehyde is a surface smooth, glossy hard and dense material, pale yellow or white color. It can be durably applied in the temperature range of -40¡«100¡ãC. Its abrasion resistance and self-lubrication property is superior to most engineering plastic with good oil resistance and peroxide resistance properties, but, its acid, alkali, and UV light resistance is poor.

Polyformaldehyde is one of five major engineering plastic, is one of the important new materials for development in polymer industry. Polyformaldehyde has good properties, wide application range and is developed quickly. Although polyformaldehyde production started early in China, due to small production scale, high production cost and unstable quality of domestic products, users still rely on imported polyformaldehyde. The following is to introduce copolymerization process. This process takes methanol as main raw material, diethylene glycol, benzene, methylal, boron trifluoride, triethylamine, sulfuric acid, alkali liquid and other solvent aid agents as accessory materials. Use DCS control system, equipped with advanced equipment to improve monomer quality, reduce energy consumption and assure polyformaldehyde production consistency.

|

| Polyformaldehyde production process

|

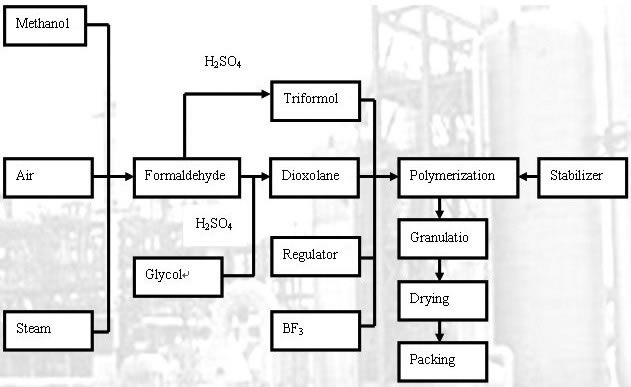

Polyformaldehyde plant consists of methanol oxidation, formaldehyde concentration, dioxolane and trioxymethylene synthesis and refine, polyformaldehyde producing processes. The supporting processes have tail gas boiler, air compressing, nitrogen generation, water cycling, soft water preparation, sewage treatment and fire fighting etc. The brief process description is as following:

Methanol is oxidized to form formaldehyde, the formaldehyde after concentration is supplied for dioxolane and trioxymethylene synthesis. The formed dioxolane and trioxymethylene after refine and purification is applied for polyformaldehyde synthesis. Finally, after stabilizing and drying process, the final product polyformaldehyde is received. |

|

Main uses of polyformaldehyde

|

Polyformaldehyde resin has excellent comprehensive properties, therefore, it is widely applied in the automibile industry, electronic industry, machinery industry, daily consumer goods , agricultural irrigation, industrial pipes, chemical industry,, instruments, appliances, and tools etc.

1.In machinery industry, polyformaldehyde is mainly used for making gears, cam, bearings, and belt wheel, conveyor belt, electric tool parts, food and milk products machinery, precision measurement valve, screw rod for chemical mixing, sausage press and construction scaffolding parts, truncheons, milk packing box. The competitive products in this area are nylon and polyester products.

2.In the automobile industry, polyformaldehyde is mainly used for making car plate components, spring pin sleeve, combination bearings, Santana car jack nut, universal joint bearings, rigid plate, spring lining sleeve, gasket, push rod ball sitting set, speedometer, gears, valves, rain brush, moveable windows and parts, door handle, safety belt buckles and electric and speaker guard. grill etc.

3.In electronic industry, polyformaldehyde is mainly used for wash machine timer, type writer convey gears, coil support, bearing support, TV set TN magnetic tape, recorder parts, potentiometer parts, counter parts etc.

4.In textile industry, polyformaldehyde is mainly used for ball pen, flexible pen parts, lighters, steam iron parts, textile machinery parts, zippers, and vehicle clothes hook, liners etc.

5.In civil construction industry, polyformaldehyde mainly is used for floating ball valve, shower spray nozzle, turncock, cold and hot water adjusting parts, venetian blinds components, pulling rod for shield, furniture wheel parts etc.

6.In daily consumer goods, polyformaldehyde is mainly used for making sports appliances such as ski board, sailing board, surfing board, bag and buckles, small appliances such as agitator, lighter and household articles.

7.In agricultural gardening and the medical instruments industries, polyformaldehyde is mainly used for making spraying device, nuts, pipe liner and spray tanks parts, pacemaker (artificial heart valvular and the artificial leg parts) etc.

|

Schematic diagram of production process is as follows |

|